Project Scope

This was the first project that was given to me as a mechanical engineering intern at Copper. The task was to develop a method to press springs into an injection molded part that was going to be a crucial component for the stove knob assembly process.

Prototyping Process

1) CAD Design

Working in SolidWorks, I pulled in the CAD parts to start conceptualizing how I was going to achieve this motion. It needed to be precise, reliable, repeatable, and easy to use. A significant factor was to make sure it was pressed to a certain depth so it wouldn’t pop out when in use.

2) First Iterations

Jumping right in I knew an arbor press was involved, so I started designing pieces that could fit onto the arbor press and could plunge the spring into the part with precision. The first few designs were 3D printed and failed to withstand any force.

3) Second Iterations

After designing a more functional locating system with 3 prongs and a strong base for the part to be easily placed onto, the next step was adding in hardware and fortifying the 3D print by introducing an aluminum plate. Here, a key is used to press the spring into the part. While it worked, it only achieved a 70% success rate.

4) Re-design & Test

In order to reduce parts waste and increase reliability, I went back to CAD, and back to the drawing board. I thought of a new design to ensure that the spring was plunged every time. This consisted of a knife edge that was machined to a fine point to cut through the plastic part. I heat treated the knife so that it was hard enough to withstand repeated uses over the production run.

5) Final Fixture

After a series of tests validating the final design, the parts were sent to the manufacturing line for production. Above, the picture on the left is the final design using 3D printed parts, heat-set inserts and a heat treated manufactured knife to plunge the spring down to a certain depth. You can see the final result of the plunged spring in the picture on the right.

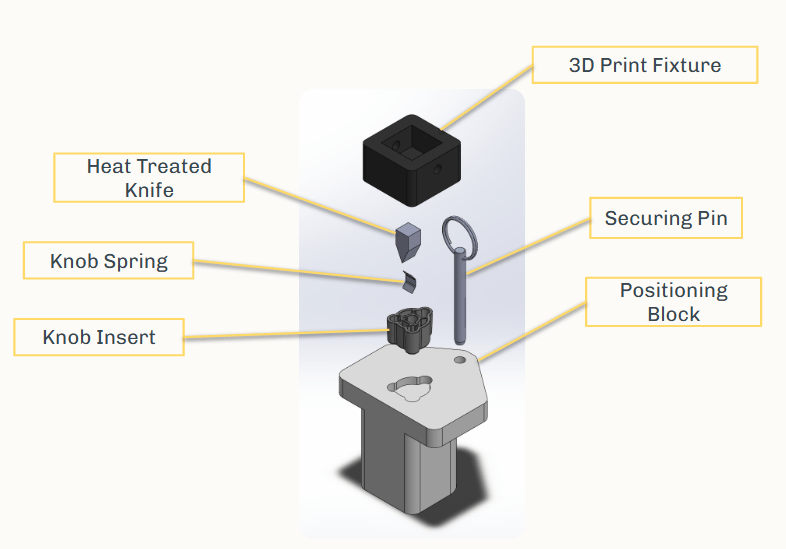

Exploded View

Here is a CAD exploded view showing how each component fit together in conjunction with an arbor press to plunge springs into the stove knob parts.

Takeaways

| What I did: | What I learned: |

| -Produced several prototypes -Contract manufacturer visits -Trained CM employees how to use my fixture -Mixed machined aluminum, steel, fasteners and 3D prints together -Heat treatment of knife feature | -How to use heat-set threaded inserts -How to make an industry level engineering drawing -Heavy prototyping iteration to get results -When to go back to the drawing board -Engineering time value and the real cost of time delays |