Project Scope

The Collegiate Wind Competition is a competition in which teams design, build, and present a unique, wind-driven power system to be tested in an on-site wind tunnel at the American Clean Power Association National Conference. My university was selected as one of ten teams nationwide to participate in this challenge. As part of the Rotor Design Team, I was responsible for designing and constructing the blades, generator, yaw and blade pitch system of the wind turbine. The aim was to optimize the electrical power production of the turbine under harsh testing conditions.

Prototyping Process

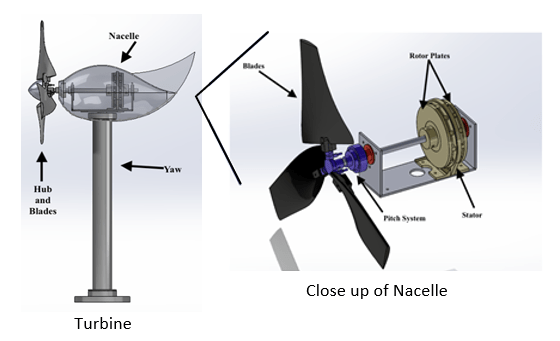

1) CAD Design

Using SolidWorks my team and I collaborated to design the subsystem parts such as the blades, generator, pitch, nacelle and yaw.

2) Machining

I worked in a machine shop and used Lathe and Mill machines to make a coil winder. Additionally, I fabricated the rotor plates for the generator as well as the structural elements of the small-scale turbine.

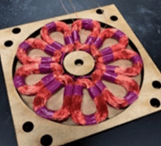

3) Coils and Stator

The stator was made by first winding the coils to a certain number of turns and then placing them in a laser cut wooden mold where the stator was then solidified.

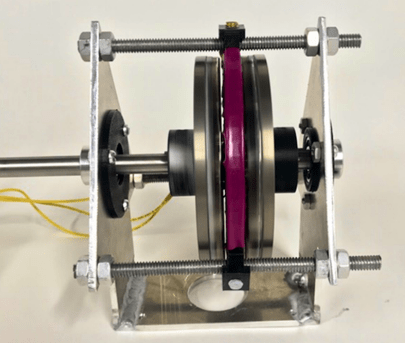

4) Generator and Pitch System

With the wind turbine in its raw form without the nacelle cover, we can examine the generator assembled where the stator is placed in the middle surrounded by two rotor plates containing magnets. As the magnets spin around the coils of wire, electricity is produced! The pitch system changes the angle of the blades, which enables greater control over power production at different wind speeds.

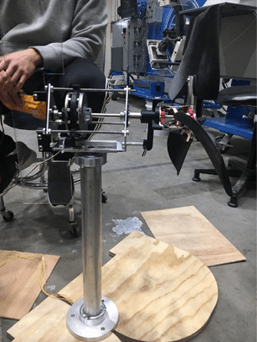

5) Assembly and Test

You can see the direct drive system from the turbine blades and pitch system leading to the generator. The nacelle sits on top of a passing yaw system that gets bolted onto a base plate in the wind tunnel. This yaw system enables the turbine to turn towards the wind in order to have the wind start rotating the blades and therefore produce power.

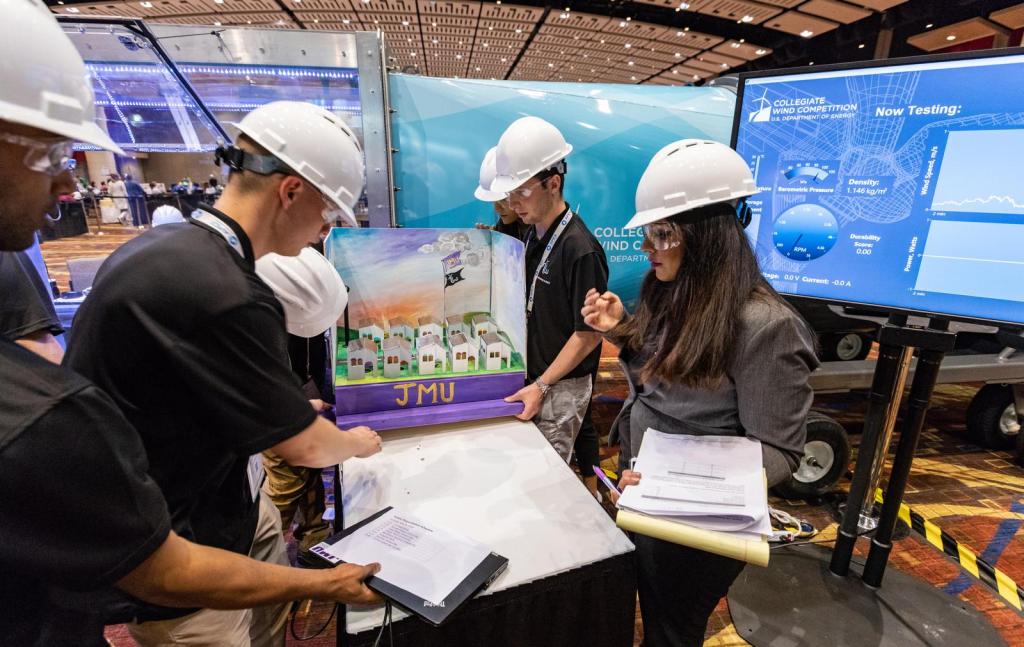

Competition Day

Here we are on competition day! The 12 teams gathered to endure a series a tests in the wind tunnels over several days. Additionally, we presented the technical elements to a panel of judges as well as a business plan for a wind farm production.

Takeaways

| What I did: | What I learned: |

| -Collaborated with 10 engineers, business and marketing students -Several rounds of design iterations after testing prototypes in wind tunnel -Fabricated metal elements of turbine -Balanced subsystem elements to optimize power output | -How to use mill, lathe and other machines in a machine shop -How to work with other engineers by effectively communicating -Designing in SolidWorks and 3D printing prototypes -How to prepare a technical presentation to judges |